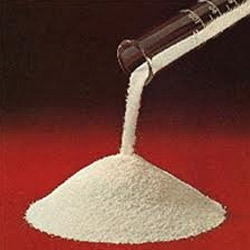

White Soda Ash

White Soda Ash Specification

- Storage

- Keep in a tightly closed container, dry, cool location

- Form

- Solid

- Purity

- 99% Min

- Smell

- Odorless

- Density

- 2.53 Gram per cubic centimeter(g/cm3)

- Molecular Formula

- Na2CO3

- Melting Point

- 851C

- Taste

- Alkaline

- Shape

- Granular / Powder

- HS Code

- 283620

- Structural Formula

- Na2CO3

- Solubility

- Highly soluble in water

- Boiling point

- Decomposes

- Molecular Weight

- 105.99 g/mol

- Other Names

- Soda Ash, Washing Soda

- Poisonous

- Yes

- Ph Level

- 11.5 (1% Solution)

- Classification

- Inorganic Alkali

- Chemical Name

- Sodium Carbonate

- CAS No

- 497-19-8

- EINECS No

- 207-838-8

- Grade

- Industrial Grade

- Standard

- GB/T 210.1-2017

- Type

- Powder

- Usage

- Industrial, Laboratory

- Main Material

- Sodium Carbonate

- Application

- Glass manufacturing, detergent, water treatment, chemical production

- Moisture Content

- 0.5%

- Shelf Life

- 24 months

- Bulk Density

- 0.86 g/cm

- Solubility in Alcohol

- Insoluble

- Heavy Metals

- <0.002%

- Appearance

- Fine White Powder

- Insoluble Matter in Water

- <0.03%

- Particle Size

- 99% Passes 180 m Sieve

- Alkalinity as Na2CO3

- >99%

- Packing

- 25/50 Kg HDPE Bags with LDPE Liner

- Iron Content

- <0.003%

White Soda Ash Trade Information

- Minimum Order Quantity

- 25 Kilograms

- Payment Terms

- Letter of Credit (L/C), Paypal, Western Union, Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 1000 Kilograms Per Week

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Australia, Eastern Europe, Western Europe, Middle East, Central America, South America, Asia, North America, Africa

- Main Domestic Market

- All India

About White Soda Ash

Broadly acknowledged for its quality, our organization is engaged in offering a vast range of Soda Ash. This exclusive product is processed by our qualified professionals using high grade chemical compounds. Our product is inspected by our quality controllers on various parameters in order to maintain its compliance with universally accepted norms. In addition to this, the offered product can be purchased at market leading rates within the promised time-frame.

Features:

- Purity

- Non hazardous

- Long shelf life

| Formula | Na2CO3 |

| Grade | Industrial |

| CAS No | 497-19-8 |

| Color | White |

| Packaging Type | HDPE Bag |

| Form | Powder |

Versatile Industrial Applications

Soda Ash is integral in diverse sectors such as glass production, detergents, water treatment, and chemical manufacturing. Its strong alkalinity (pH level of 11.5 in a 1% solution) and high solubility in water make it suitable for processes requiring precise chemical reactions and purity standards. As an industrial and laboratory-use product, it serves as a reliable and cost-effective solution for bulk requirements in India and worldwide.

Safe Handling and Storage

Supplied in robust 25/50 kg HDPE bags with LDPE liners, White Soda Ash must be maintained in a tightly closed container stored in a dry, cool area. The products non-poisonous, odorless nature ensures safe handling, provided proper storage protocols are followed. Its moisture content is 0.5%, protecting it from caking or quality loss, while the extended shelf life of 24 months supports long-term inventory management.

FAQs of White Soda Ash:

Q: How should White Soda Ash be stored to maintain its quality?

A: White Soda Ash should be stored in a tightly closed container in a dry, cool location, away from moisture and direct sunlight. This prevents caking, moisture uptake, and maintains its shelf life of 24 months.Q: What are the primary industrial applications of White Soda Ash?

A: White Soda Ash is extensively used in glass manufacturing, detergent production, water treatment, and various chemical syntheses due to its strong alkalinity, high water solubility, and stable chemical properties.Q: When is Soda Ash commonly added during glass production?

A: In glass manufacturing, Soda Ash is typically introduced during the melting phase. It lowers the melting point of silica, enabling efficient glass formation and reducing energy consumption.Q: Where is White Soda Ash most effectively utilized in water treatment processes?

A: White Soda Ash is utilized during the pH adjustment and softening stages in water treatment plants, effectively neutralizing acidity and precipitating magnesium and calcium ions for improved water quality.Q: What is the recommended process for handling bulk Soda Ash safely?

A: Operators should use appropriate personal protective equipment, such as gloves and dust masks, and handle the bags gently to avoid spills. Working in well-ventilated areas minimizes dust inhalation during transfer and dosing operations.Q: What are the benefits of using high-purity Soda Ash with minimal impurities?

A: High-purity Soda Ash ensures low heavy metal and iron content, contributing to consistent process quality and compliance with industrial standards, especially in sensitive applications like glassmaking and chemical synthesis.Q: How can the fine powder form of Soda Ash enhance its utility in industrial settings?

A: The fine powder form (99% passes a 180 m sieve) offers superior dispersion and rapid dissolution, streamlining mixing and reaction rates in industrial and laboratory processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Chemicals Category

Tertiary Butanol 99.9%

Price 90 INR / Kilograms

Minimum Order Quantity : 25 Kilograms

Purity : 99.9%

Application : Other, Used as a solvent and intermediate in chemical synthesis

Form : Other, Liquid/Solid

Storage : Other, Store in cool, dry, wellventilated place, tightly closed container

Dioctyl Phthalate

Price 80 INR

Minimum Order Quantity : 25 Kilograms

Purity : 99% minimum

Application : Other, Used as plasticizer for PVC, rubber, and other polymers

Form : Other, Clear oily liquid

Storage : Other, Keep in tightly closed container, store in cool, dry, ventilated area

Epichlorohydrin Chemical

Price 23000 INR

Minimum Order Quantity : 1 ,

Purity : 99%

Application : Other, Used in production of epoxy resins, surfactants, elastomers, water treatment chemicals, synthetic glycerin, and as a solvent

Form : Other, Clear colorless liquid

Storage : Other, Store in cool, dry, wellventilated area away from heat and sources of ignition

Ortho Cresol

Price 44000 INR

Minimum Order Quantity : 1 Dram

Purity : 99% min

Application : Other, Used as an intermediate in dye, resin, and pesticide manufacturing, and in disinfectants

Form : Other, Liquid/Crystal

Storage : Other, Store in a tightly sealed container, in a cool, dry, wellventilated place

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS