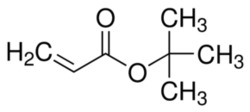

Tert-Butyl Acrylate

Tert-Butyl Acrylate Specification

- Residue on Ignition

- 0.01%

- Molecular Weight

- 128.17 g/mol

- EINECS No

- 216-774-5

- Acid Value

- 0.05%

- HS Code

- 2916.1400

- Place of Origin

- China

- Heavy Metal (%)

- 0.001%

- Viscosity

- 0.75 mPas (at 25C)

- Particle Size

- Not applicable (liquid product)

- Melting Point

- -78 C

- Assay

- >=99%

- Storage

- Store in a cool, dry, and well-ventilated area. Keep container tightly closed.

- Boiling point

- 120122 C

- Moisture (%)

- 0.05%

- Molecular Formula

- C7H12O2

- Other Names

- TBA; Tert-Butyl 2-propenoate

- CAS No

- 1663-39-4

- Type

- Industrial Chemical

- Grade

- Industrial / Technical

- Usage

- Used as monomer/intermediate in synthesis of acrylic resins, coatings, adhesives, and plastics

- Purity

- 99.0%

- Appearance

- Clear, colorless liquid

- Application

- Acrylic resins, paint, adhesives, emulsions, coatings, fiber and polymer industries

- Raw Material

- Acrylic acid, Isobutylene

- Smell

- Characteristic, ester-like odor

- Color

- Colorless to pale yellow

- Form

- Liquid

Tert-Butyl Acrylate Trade Information

- Minimum Order Quantity

- 25 Kilograms

- Payment Terms

- Letter of Credit (L/C), Western Union, Paypal, Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 500 Kilograms Per Week

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Australia, North America, Eastern Europe, Western Europe, Middle East, South America, Asia, Central America, Africa

- Main Domestic Market

- All India

About Tert-Butyl Acrylate

Tert-Butyl Acrylate

Tert-Butyl Acrylate is a monomer used to produce poly(tert-butyl acrylate) (PtBA) polymers and copolymers, and poly(acrylic acid) polyelectrolyte brushes.

Known by common names of TBA; T-BUTYL ACRYLATE; Butyl acrylate; 1-butylacrylate; Butyl propenoate; acrylatedebutyle;BUTYL-2-ACRYLATE; Acrylic acid butyl; n-Butyl propenoate, Butyl Acrylate comes with molecular formula of C7H12O2. It is a colorless liquid with slight solubility in water as well as features sharp characteristic odor. With flash point of 105F and density of 7.5 lb / gal, it finds use in production of caulks, sealants, paints, coatings, adhesives.

Specification

| Grade Standard | Technical Grade |

| Physical State | Liquid |

| Usage | Industrial,Commerical |

| Packaging Type | Drum |

| Packaging Size | 180 Kgs |

High-Purity Industrial Monomer

Tert-Butyl Acrylate stands out for its exceptional purity (99.0%) and reliable performance in industrial applications. Produced using acrylic acid and isobutylene, it serves as a core component in the manufacture of acrylic resins, coatings, and adhesives. Its stable molecular structure ensures consistent quality and effectiveness.

Essential for Modern Manufacturing

This versatile raw material is widely used in numerous industries including paints, coatings, plastics, adhesives, and fiber production. Its compatibility with various solvents and polymers makes it invaluable for creating high-performance materials and enhancing product durability.

Safety and Storage Guidelines

Given its flammable nature (hazard class 3) and flash point of 19C, TBA requires careful handling. Always store in tightly closed containers in cool, dry, well-ventilated areas. Complying with recommended safety protocols is essential for maintaining its stability and prolonging shelf life.

FAQs of Tert-Butyl Acrylate:

Q: How should Tert-Butyl Acrylate be stored to maintain its quality and stability?

A: Tert-Butyl Acrylate should be stored in a cool, dry, and well-ventilated area, with containers kept tightly closed. Proper storage conditions help maintain its stability and ensure a shelf life of up to 12 months from the production date.Q: What are the main industrial uses and benefits of Tert-Butyl Acrylate?

A: Tert-Butyl Acrylate is primarily used as a monomer or intermediate in the production of acrylic resins, coatings, adhesives, emulsions, and plastics. Its high purity and compatibility with various materials improve product quality and increase durability in end applications.Q: When should safety precautions be implemented while handling TBA?

A: Safety precautions must be implemented at all stages when handling, transporting, or storing TBA due to its classification as a flammable liquid (hazard class 3) and low flash point of 19C. Protective equipment, proper ventilation, and fire hazard controls are essential.Q: Where is Tert-Butyl Acrylate typically manufactured and exported from?

A: Tert-Butyl Acrylate is commonly manufactured in China and supplied by exporters and importers worldwide, including major markets such as India. It is distributed in drums, IBCs, or specialized packaging as required by customers.Q: What is the recommended process for using TBA in industrial applications?

A: TBA is introduced as a monomer or reactive intermediate during polymerization or blending processes. It is added according to the formulation requirements for acrylic resins, coatings, or adhesives, ensuring compatibility with other raw materials such as alcohols and ethers.Q: How does Tert-Butyl Acrylate benefit manufacturers in the acrylic and coatings industries?

A: TBA offers high reactivity and purity, allowing manufacturers to achieve optimal polymerization, improved product clarity, and enhanced mechanical properties in end products like coatings, paints, and adhesives.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pharmaceutical Chemicals Category

Methyl n-Propyl Ketone

Price 475 INR

Minimum Order Quantity : 25 Kilograms

Purity : 99%

Molecular Formula : C5H10O

Place of Origin : India

Form : Liquid

Pyrogallol

Price 320000 INR / Dram

Minimum Order Quantity : 1 Dram

Purity : 99% Minimum

Molecular Formula : C6H6O3

Place of Origin : India

Form : Solid

Hydrobromic Acid

Price 26250 INR

Minimum Order Quantity : 1 ,

Purity : 48%

Molecular Formula : HBr

Place of Origin : India

Form : Liquid

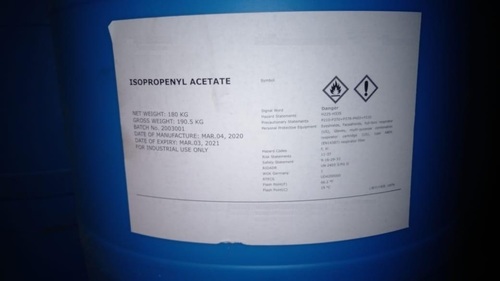

ISO Propenyl Acetate

Price 1150 INR / Kilograms

Minimum Order Quantity : 180 KGS Kilograms

Purity : 99%

Molecular Formula : C5H8O2

Place of Origin : CHINA

Form : Liquid

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS