Polypropylene Glycol

Polypropylene Glycol Specification

- HS Code

- 29053990

- Assay

- >99%

- Molecular Formula

- C3H8O2 (repeating unit)

- EINECS No

- 500-039-8

- Melting Point

- -60C to -40C

- Ph Level

- Neutral (6.2-7.0)

- Particle Size

- Not applicable (liquid)

- Heavy Metal (%)

- <0.001%

- Viscosity

- 100 800 mPas @ 25C (depends on molecular weight)

- Moisture (%)

- <0.1%

- Loss on Drying

- <0.1%

- Place of Origin

- India

- Residue on Ignition

- <0.05%

- Storage

- Store in tightly closed container in a cool, dry place

- Acid Value

- <0.05 mgKOH/g

- Molecular Weight

- Varies (commonly 400-4000 g/mol depending on grade)

- Boiling point

- 180C - 250C

- Other Names

- PPG, Poly(oxypropylene) glycol

- CAS No

- 25322-69-4

- Type

- Polyether Polyol

- Grade

- Industrial grade

- Usage

- Manufacturing of polyurethane foams, surfactants, lubricants, hydraulic fluids, chemical intermediates

- Purity

- >99%

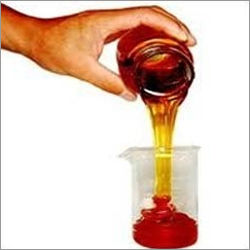

- Appearance

- Clear viscous liquid

- Application

- Polyurethane, adhesives, coatings, surfactant formulation

- Raw Material

- Propylene Oxide

- Smell

- Slight odor

- Color

- Colorless to pale yellow

- Form

- Liquid

- Solubility

- Soluble in water, acetone, and alcohols

- Biodegradability

- Readily biodegradable

- Refractive Index

- 1.4351.438 @ 20C

- Hazard Information

- Non-hazardous in normal use; avoid contact with eyes and prolonged skin exposure

- pH Stability

- Stable at pH 68

- Hydroxyl Value

- 50 560 mgKOH/g

- Flash Point

- >150C

- Density

- 0.99 1.02 g/cm @ 25C

- Surface Tension

- ~36 dyn/cm @ 25C

- Shelf Life

- 2 years under recommended storage conditions

- Toxicity

- Low acute toxicity

- Packaging

- Drums, IBCs, bulk tanker

Polypropylene Glycol Trade Information

- Minimum Order Quantity

- 1 Dram

- Payment Terms

- Paypal, Letter of Credit (L/C), Western Union, Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 10 Drams Per Week

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- South America, Middle East, Central America, Western Europe, Australia, Asia, Eastern Europe, North America, Africa

- Main Domestic Market

- All India

About Polypropylene Glycol

Polypropylene Glycol

Our organization is instrumental in offering a wide range of Polypropylene Glycol. The offered Polypropylene glycol is processed according to the market norms by utilizing best grade chemical compounds in accurate composition. Apart from this, we offer this Polypropylene glycol in number of packaging options with different stipulations at affordable rates.

Features:

- Highly effective

- Non reactive

- Safe usage

Available with various molecular weights like:

PPG - 400

PPG - 1000

PPG - 2000

PPG - 4000

Specification

| Density | 946 kg/m3 |

| CAS No | 57-55-6 |

| Purity % | >99% |

| Packaging Details | 200 litres Drum |

| Grade Standard | Industrial Grade |

| Physical State | Liquid |

| Usage/Application | Artificial smoke,Solvent for food colors and flavors,Humectant in medicines or food products |

| Synonyms | Methyl ethyl glycol |

| Melting point | 160 deg C |

| Formula | (C3H6)n |

What makes Polypropylene Glycol valuable for industry?

PPG stands out for its versatility, chemical stability, and purity, exceeding 99%. With excellent water solubility, thermal stability, and low toxicity, it is a preferred raw material for polyurethane foams, adhesives, surfactants, and lubricants. Its consistent quality and biodegradability contribute to efficient and sustainable manufacturing processes.

Handling and Storage Guidelines

It is best to store Polypropylene Glycol in tightly closed containers in a cool, dry environment to preserve its properties over the recommended two-year shelf life. Standard packaging options include drums, IBCs, and bulk tankers, catering to various scale requirements. The product remains stable under neutral to slightly alkaline pH conditions and does not pose significant hazards under normal circumstances.

Environmental and Safety Aspects

Polypropylene Glycol exhibits low acute toxicity and is considered non-hazardous during standard handling. Avoid contact with eyes and prolonged skin exposure to minimize potential irritation. It is readily biodegradable, supporting environmentally responsible use and disposal. Regular quality checks ensure minimal impurities and heavy metals, enhancing workplace safety.

FAQs of Polypropylene Glycol:

Q: How should Polypropylene Glycol be stored to maintain its shelf life?

A: Polypropylene Glycol should be kept in tightly closed containers, placed in a cool and dry location to ensure stability and preserve quality for up to two years. Avoid prolonged exposure to moisture or unsuitable temperatures.Q: What are the primary industrial applications of Polypropylene Glycol?

A: PPG is frequently used in manufacturing polyurethane foams, surfactants, hydraulic fluids, lubricants, adhesives, coatings, and as a chemical intermediate in various formulations due to its solubility and stability.Q: When is it necessary to use additional protective measures while handling Polypropylene Glycol?

A: Normal use does not require extensive protection, but safety goggles and gloves are advisable when handling to prevent eye contact and prolonged skin exposure, particularly in large-scale or prolonged operations.Q: Where is Polypropylene Glycol commonly sourced from?

A: This product is predominantly manufactured and supplied in India, using propylene oxide as the primary raw material, with reliable exporter, importer, and supplier networks available.Q: What process is used in producing Polypropylene Glycol?

A: Polypropylene Glycol is synthesized via the polymerization of propylene oxide, which results in various molecular weight grades tailored for specific industrial needs.Q: How does using Polypropylene Glycol benefit product performance?

A: PPG enhances product quality by providing chemical stability, high purity, and compatibility in water-based systems. Its biodegradability and low toxicity also support eco-friendly practices.Q: Is Polypropylene Glycol suitable for use in environmentally sensitive applications?

A: Yes, PPG is readily biodegradable and features low acute toxicity, making it suitable for manufacturing processes with environmental and safety considerations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pharma Chemicals Category

Para Toluene Sulfonic Acid

Price 75 INR

Minimum Order Quantity : 25 Kilograms

Purity : 99% Min

Storage : Other, Store in cool, dry place; tightly sealed

Form : Solid

Place of Origin : India

Dimethylformamide Chemical

Price 67 INR

Minimum Order Quantity : 25 Kilograms

Purity : 99.8%

Storage : Other, Store in tightly closed container, in a cool, dry, wellventilated area away from heat and sources of ignition

Form : Liquid

Place of Origin : India

Liquid Toluene

Price 12000 INR

Minimum Order Quantity : 1 Dram

Purity : 99.9% min

Storage : Other, Store in tightly closed containers in a cool, dry, wellventilated area away from sources of ignition

Form : Liquid

Place of Origin : India

Liquid Propionaldehyde

Price 35200 INR

Minimum Order Quantity : 1 Dram

Purity : 99%

Storage : Room Temperature

Form : Liquid

Place of Origin : INDIA

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS