Diethyl Phthalate

Diethyl Phthalate Specification

- Form

- Clear, colorless, oily liquid

- Smell

- Faint aromatic odour

- Storage

- Store in tightly closed container, in a cool, dry, well-ventilated place

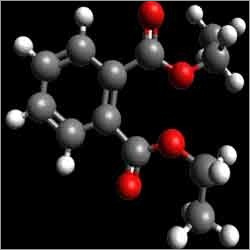

- Structural Formula

- C6H4(COOC2H5)2

- Solubility

- Insoluble in water, soluble in ethanol, ether, acetone and benzene

- Taste

- Bitter taste

- Ph Level

- Neutral

- Melting Point

- -1.5C to -0.5C

- Purity

- 99% (Typical)

- HS Code

- 29173920

- Poisonous

- Yes

- Density

- 1.118 Gram per cubic centimeter(g/cm3)

- Boiling point

- 298C

- Other Names

- DEP, Ethyl phthalate

- Refractive Rate

- 1.500 (at 20C)

- Shape

- Liquid

- Molecular Formula

- C12H14O4

- Molecular Weight

- 222.24 g/mol

- Classification

- Phthalate Ester

- Chemical Name

- Diethyl Phthalate

- CAS No

- 84-66-2

- EINECS No

- 203-550-1

- Grade

- Industrial Grade, Cosmetic Grade

- Standard

- Meets technical & industrial regulations

- Type

- Chemical Compound

- Usage

- Industrial, Cosmetic, Laboratory chemicals

- Main Material

- Diethyl Phthalate

- Application

- Used as plasticizer in cellulose ester plastics, cosmetic formulations, perfumery compounds, and as a solvent

Diethyl Phthalate Trade Information

- Minimum Order Quantity

- 25 Kilograms, ,

- Payment Terms

- Letter of Credit (L/C), Western Union, Paypal, Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 1000 Kilograms, , Per Week

- Delivery Time

- 1-2 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Western Europe, Australia, North America, Eastern Europe, Middle East, Africa, South America, Asia, Central America

- Main Domestic Market

- All India

About Diethyl Phthalate

Features:

- Safe in use

- Do not harm skin

- Reasonable prices

- Hygienically processed

Specification

| Boiling point | 295 deg C |

| Molar mass | 222.24 g/mol |

| Formula | C12H14O4 |

| Density | 1.12 g/cm3 |

Exceptional Plasticizing and Solvent Properties

Diethyl Phthalate is recognized for its superior plasticizing capability in cellulose ester plastics and excellent solvency in various industrial applications. Its compatibility with most resins and polymers ensures effective formulation for plastics, personal care products, and perfumery compounds. The products high purity further enhances its performance and contributes to the stability and integrity of finished goods.

Reliable Storage, Handling, and Safety

DEP maintains stability under recommended storage conditions for up to two years. The product should be stored in tightly closed containers, away from heat sources, in a cool and well-ventilated area. Though not classified as acutely toxic, it is essential to avoid ingestion and prolonged or excessive exposure. Proper handling ensures safe usage across industrial and laboratory settings.

FAQs of Diethyl Phthalate:

Q: How should Diethyl Phthalate be stored to maintain its shelf life?

A: Diethyl Phthalate should be stored in tightly closed containers, kept in cool, dry, well-ventilated spaces away from heat or ignition sources. Proper storage ensures stability and a shelf life of up to two years.Q: What are the recommended industrial and cosmetic uses of Diethyl Phthalate?

A: Diethyl Phthalate is primarily used as a plasticizer in cellulose ester plastics, a solvent in cosmetic formulations, and a carrier for fragrance in perfumery compounds. It is also utilized in laboratory chemicals due to its compatibility with various materials.Q: When is Diethyl Phthalate considered beneficial during manufacturing processes?

A: Diethyl Phthalate is beneficial when manufacturers require enhanced flexibility, workability, and solvency in formulations. Its high compatibility and purity make it invaluable for producing soft plastics, cosmetic ingredients, and stabilized industrial products.Q: Where is Diethyl Phthalate typically available for industrial procurement?

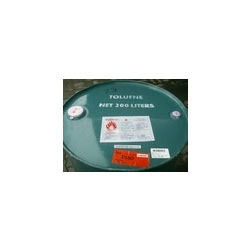

A: DEP can be sourced from chemical exporters, importers, and suppliers in India. It is commonly available in standard 200L drums, IBC tanks, or custom packaging as required by customers.Q: Can Diethyl Phthalate be used with all types of resins and plastics?

A: Yes, Diethyl Phthalate is largely compatible with most resins, polymers, and plastic materials, making it a versatile choice for a range of industrial applications.Q: What is the process for using Diethyl Phthalate in formulations?

A: Diethyl Phthalate is added in precise quantities to formulations as a plasticizer or solvent. Its low volatility and high boiling point contribute to product stability and efficiency during the blending and processing stages.Q: What benefits does Diethyl Phthalate provide compared to other plasticizers?

A: Diethyl Phthalate offers excellent compatibility, high purity (99%), and outstanding performance as both a plasticizer and solvent. It improves product flexibility, extends shelf life, and is suitable for both technical and cosmetic applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Chemicals Category

Tertiary Butanol

Price 21780 INR

Minimum Order Quantity : 1 Dram

Application : Other, Used as a solvent, intermediate, denaturant for ethanol, manufacturing flavors and fragrances

Storage : Other, Store in a cool, dry, wellventilated area away from incompatible substances

Form : Other, Crystalline or powder

Purity : 99% Minimum

White Sodium Borohydride Powder

Price 1600 INR

Minimum Order Quantity : 25 Kilograms

Application : Other, Reducing agent, pharmaceuticals, water treatment, pulp and paper industry

Storage : Other, Keep tightly sealed, store in a cool dry place, away from moisture

Form : Solid

Purity : 98% minimum

Liquid Toluene Diisocyanate

Price 150 INR

Minimum Order Quantity : 25 Kilograms

Application : Other, Used in the manufacture of polyurethane foams, elastomers, coatings, adhesives, and sealants

Storage : Other, Store in cool, dry, and wellventilated area; keep container tightly closed

Form : Liquid

Purity : 99% min

Liquid Toluene

Price 12100 INR

Minimum Order Quantity : 1 Dram

Application : Other, Used as an industrial solvent, manufacturing of paints, thinners, adhesives, chemical intermediates, pharmaceuticals

Storage : Other, Store in cool, ventilated, and dry place away from sources of ignition

Form : Liquid

Purity : 99.9%

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free