Liquid Diethylenetriamine

MOQ : 50 Kilograms

Liquid Diethylenetriamine Specification

- Density

- 0.95 Gram per cubic centimeter(g/cm3)

- Purity

- 99%

- Melting Point

- -39 C

- Molecular Formula

- C4H13N3

- Size

- Available upon request (commonly 200L drums)

- Ph Level

- Alkaline (strong base)

- Packaging Type

- Drum, IBC, or bulk

- Storage Instructions

- Store in tightly closed containers in a cool, dry, ventilated area away from incompatible substances

- Shelf Life

- 24 months if properly stored

- CAS No

- 111-40-0

- Flash Point

- 100C (closed cup)

- Boiling point

- 207 C

- Physical State

- Liquid

- Molecular Weight

- 103.17 g/mol

- Usage

- Industrial chemical, used in resins, chelating agents, surfactants, and adhesives

- Grade

- Industrial Grade

- Type

- Liquid

- Application

- Chemical intermediate, epoxy hardeners, corrosion inhibitors, fuel additives

- Appearance

- Colorless to light yellow liquid

- Purity(%)

- 99%

- Vapor Pressure

- 0.2 mmHg at 25°C

- Hazard Class

- Corrosive

- UN Number

- 2079

- Viscosity

- 4.1 mPa·s at 25°C

- Autoignition Temperature

- 385°C

- EC Number

- 203-865-4

- Compatibility

- Avoid contact with acids, oxidizers, and reducing agents

- Refractive Index

- 1.464

- Stability

- Stable under recommended storage conditions

- Solubility

- Miscible with water

- Odor

- Ammoniacal

Liquid Diethylenetriamine Trade Information

- Minimum Order Quantity

- 50 Kilograms

- Payment Terms

- Paypal, Letter of Credit (L/C), Western Union, Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 500 Kilograms Kg Per Week

- Delivery Time

- 1-2 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Middle East, Africa, Central America, Western Europe, Asia

- Main Domestic Market

- All India

About Liquid Diethylenetriamine

Being a trusted supplier, exporter, trader, distributor, retailer and importer of the domain, we provide excellent Diethylenetriamine, which can be availed from us at most affordable prices. Under the guidance of experts, this is processed using premium quality ingredients and ultra-modern technology in tandem with set international standards and norms. Thus, our offered Diethylenetriamine provides effective results. In order to suit the diverse preferences of the clients, we deliver this in pre-defined time frame in various packaging options and quantities.

Features:

- Effective

- Enhanced shelf life

- High purity

- Accurate composition

Versatile Industrial Applications

Diethylenetriamine excels as an integral component in chemical production. It is widely utilized in synthesizing epoxy resins, chelating agents, corrosion inhibitors, and adhesives, making it a preferred choice in the industrial sector. Its compatibility with diverse formulations amplifies productivity in fuel additives and surfactant manufacturing. With its strong basicity, it plays a vital role in various complex chemical processes.

Safe Handling and Storage

Ensuring the safety of personnel is crucial when handling Liquid Diethylenetriamine. Store the chemical in tightly sealed containers in cool, dry, and well-ventilated areas, away from acids, oxidizers, and reducing agents to maintain stability. Its corrosive nature requires proper PPE and adherence to hazard protocols. Suitable packaging options, such as drums or IBCs, support efficient logistics and minimize exposure risks.

FAQs of Liquid Diethylenetriamine:

Q: How should Liquid Diethylenetriamine be stored for optimal shelf life?

A: Liquid Diethylenetriamine should be stored in tightly closed containers in a cool, dry, and ventilated area, away from incompatible substances such as acids, oxidizers, and reducing agents. Proper storage ensures the product retains its quality for up to 24 months.Q: What are the main industrial uses of Diethylenetriamine?

A: Diethylenetriamine is primarily used as a chemical intermediate in the manufacturing of epoxy hardeners, corrosion inhibitors, fuel additives, chelating agents, adhesives, and surfactants. Its versatility makes it valuable across multiple chemical processes.Q: When should Diethylenetriamine be avoided during chemical processing?

A: Diethylenetriamine should be avoided in processes involving acids, strong oxidizers, and reducing agents, as interaction with these substances can lead to hazardous reactions due to its corrosive nature and strong basicity.Q: Where is this chemical typically packaged and supplied from?

A: Diethylenetriamine is commonly packaged in drums, IBCs, or supplied in bulk quantities. The product is widely exported, imported, and distributed by suppliers throughout India, catering to various industrial needs.Q: What process should be followed for the safe handling of this corrosive liquid?

A: Personnel handling Diethylenetriamine must use proper personal protective equipment, such as gloves, goggles, and resistant clothing, due to its corrosive hazard class. Implementing standard safety protocols and restricted access to incompatible substances is recommended.Q: What benefits does Diethylenetriamine offer in industrial applications?

A: The high purity (99%) and strong alkaline properties make Diethylenetriamine highly effective in enhancing chemical reactions, especially in epoxy hardeners and corrosion inhibitors. Its stability and solubility enable efficient production workflows.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Lab Chemicals Category

N Butanol

Price 20000 INR

Minimum Order Quantity : 10 Drams

Purity(%) : 99%

Type : Other, Alcohol

Grade : Industrial Grade

CAS No : 71363

Sodium Percarbonate Tablet

Price 75 INR

Minimum Order Quantity : 50 Kilograms

Purity(%) : 99%

Type : Other, Cleaning Chemical / Bleaching Agent

Grade : Industrial Grade

CAS No : 15630894

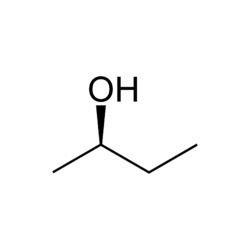

2-Butanol

Price 150 INR

Minimum Order Quantity : 1 Kilograms

Purity(%) : 99%

Type : Industrial Lab Chemicals

Grade : Technical Grade

1,3 Butylene Glycol

Price 1000.00 INR

Minimum Order Quantity : 200 Kilograms, Kilograms

Purity(%) : 99%

Type : Industrial Lab Chemicals

Grade : Technical

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS