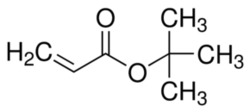

Butyl Acrylate

Butyl Acrylate Specification

- Melting Point

- -64 C

- Boiling point

- 145-151 C

- Loss on Drying

- Not applicable (volatile liquid)

- Residue on Ignition

- 0.01%

- Molecular Formula

- C7H12O2

- HS Code

- 29161200

- Place of Origin

- India

- Viscosity

- 0.7 mPas at 20 C

- Storage

- Store in a cool, dry, well-ventilated area away from sunlight and incompatible materials

- Ph Level

- Not applicable (neutral organic ester)

- EINECS No

- 205-480-7

- Molecular Weight

- 128.17 g/mol

- Moisture (%)

- 0.05%

- Particle Size

- Not applicable (liquid product)

- Assay

- >= 99.0%

- Heavy Metal (%)

- 0.0001%

- Acid Value

- 0.01% (as acrylic acid)

- Other Names

- n-Butyl Acrylate, Butyl Ester of Acrylic Acid

- CAS No

- 141-32-2

- Type

- Industrial Chemical

- Grade

- Industrial / Commercial

- Usage

- Intermediate for organic synthesis, used in paints, adhesives, sealants, coatings, plastics, and textiles

- Purity

- 99.0%

- Appearance

- Clear liquid

- Application

- Paints, adhesives, coatings, textiles, resins, plastics, and sealants

- Raw Material

- Acrylic acid, n-Butanol

- Smell

- Fruity, pungent odor

- Color

- Colorless to slightly yellow

- Form

- Liquid

Butyl Acrylate Trade Information

- Minimum Order Quantity

- 25 ,

- Payment Terms

- Paypal, Letter of Credit (L/C), Western Union, Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 500 Per Week

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Australia, North America, Eastern Europe, Western Europe, Middle East, Africa, South America, Asia, Central America

- Main Domestic Market

- All India

About Butyl Acrylate

Butyl Acrylate

Butyl Acrylate is a monomer used to produce poly(tert-butyl acrylate) (PtBA) polymers and copolymers, and poly(acrylic acid) polyelectrolyte brushes.

Known by common names of TBA; T-BUTYL ACRYLATE; Butyl Acrylate; 1-butylacrylate; Butyl propenoate; acrylatedebutyle;BUTYL-2-ACRYLATE; Acrylic acid butyl; n-Butyl propenoate, Butyl Acrylate comes with molecular formula of C7H12O2. It is a colorless liquid with slight solubility in water as well as features sharp characteristic odor. With flash point of 105F and density of 7.5 lb / gal, it finds use in production of caulks, sealants, paints, coatings, adhesives.

Specification

| Form of Chemicals | Liquid |

| Physical State | Liquid |

| Usage | Industrial,Commerical |

| Packaging Type | Packet |

| Grade Standard | Technical Grade |

Versatile Industrial Applications

Butyl Acrylate serves as a crucial raw material for a wide variety of industries, including paints, coatings, adhesives, textiles, plastics, and sealants. Its ability to impart flexibility and durability to polymers makes it especially valuable for enhancing product performance during manufacturing.

Safe Storage and Handling Guidelines

For maximum stability and safety, Butyl Acrylate should be stored in cool, dry, and well-ventilated conditions, ensuring it remains away from sunlight and incompatible materials. Always use appropriate personal protective equipment, as the substance has a low flash point and a pungent, fruity odor.

Chemical and Physical Properties

This organic ester features a molecular formula C7H12O2 and a molecular weight of 128.17 g/mol. It displays a clear liquid appearance, with a density of 0.8840.886 g/cm at 20 C. Its volatility (boiling point: 145151 C) and low viscosity (0.7 mPas at 20 C) make it easy to handle in industrial processes.

FAQs of Butyl Acrylate:

Q: How is Butyl Acrylate utilized in industrial manufacturing?

A: Butyl Acrylate acts as a building block in the synthesis of various polymers, which are then formulated into products such as paints, adhesives, sealants, coatings, plastic resins, and textiles. Its role is to enhance flexibility, adhesion, and weather resistance in end applications.Q: What are the recommended storage conditions for Butyl Acrylate?

A: To ensure long-term stability, Butyl Acrylate should be stored in a cool, dry, and well-ventilated area, kept away from direct sunlight and incompatible materials. Proper storage minimizes risks associated with its low flash point (38 C, closed cup) and preserves product quality.Q: When should personal protective equipment (PPE) be worn when handling Butyl Acrylate?

A: Suitable PPE, including gloves, goggles, and protective clothing, should always be worn during handling or transfer, as Butyl Acrylate has a pungent odor and can be irritating. Proper ventilation and careful handling also help maintain safety.Q: What is the benefit of using Butyl Acrylate in coatings and adhesives?

A: Products formulated with Butyl Acrylate benefit from improved flexibility, adhesion, and resistance to weathering. This quality ensures longer-lasting performance for coatings and adhesives used in construction, automotive, and industrial settings.Q: Where is Butyl Acrylate typically produced and supplied from?

A: Butyl Acrylate is manufactured, exported, and supplied notably from India, often by specialized chemical suppliers serving both domestic and international markets as intermediates for organic synthesis.Q: What process safeguards the stability of Butyl Acrylate during storage and transportation?

A: To maintain stability, Butyl Acrylate contains a small amount of inhibitor (~10-15 ppm MEHQ) that prevents premature polymerization. Following recommended storage protocols further ensures the compound remains stable throughout its lifecycle.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pharmaceutical Chemicals Category

Triethyl Orthoformate

Price 34000 INR

Minimum Order Quantity : 1 Dram

Color : Colorless

Purity : 99.0%

CAS No : 122510

Form : Liquid

1-Bromo 3-Chloropropane

Price 56100 INR

Minimum Order Quantity : 1 Dram

Color : Other, Colorless to pale yellow

Purity : 99%

CAS No : 109706

Form : Liquid

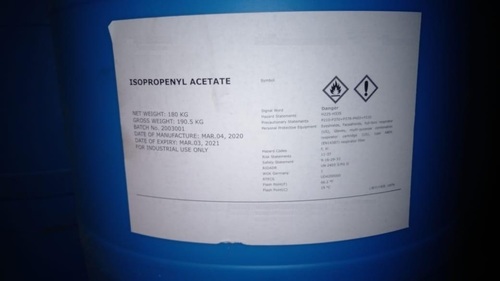

ISO Propenyl Acetate

Price 1150 INR / Kilograms

Minimum Order Quantity : 180 KGS Kilograms

Color : White

Purity : 99%

CAS No : 108225

Form : Liquid

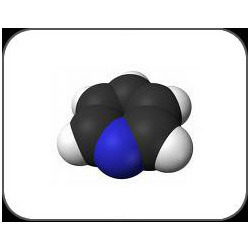

2-OH Pyridine

Price 900 INR

Minimum Order Quantity : 25

Color : Blue

Purity : 99%

CAS No : 100868.

Form : Liquid

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS