Methylene Dichloride MDC

Methylene Dichloride MDC Specification

- Melting Point

- -95C

- Ph Level

- Not applicable (non-aqueous)

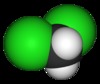

- Molecular Formula

- CH2Cl2

- Assay

- 99.9% min

- Particle Size

- Not applicable (liquid)

- Viscosity

- 0.44 mPas (at 20C)

- Heavy Metal (%)

- 0.0001%

- Acid Value

- 0.0005%

- Boiling point

- 39.6C

- Moisture (%)

- 0.01%

- EINECS No

- 200-838-9

- HS Code

- 29031200

- Residue on Ignition

- 0.005%

- Molecular Weight

- 84.93 g/mol

- Storage

- Store in cool, ventilated area away from heat and ignition sources

- Place of Origin

- India

- Other Names

- Dichloromethane, MDC, Methylene Chloride

- CAS No

- 75-09-2

- Type

- Chemical Solvent

- Grade

- Industrial, Technical, Pharmaceutical

- Usage

- Industrial, Pharmaceutical, Adhesives, Paint Remover

- Purity

- 99.9%

- Appearance

- Clear Liquid

- Application

- Solvent in paint removers, adhesives, pharmaceuticals, metal cleaning, extraction processes

- Raw Material

- Chloromethane, Chlorine

- Smell

- Chloroform-like, sweet odor

- Color

- Colorless

- Form

- Liquid

- Vapor Pressure

- 475 mm Hg at 20C

- Stability

- Stable under recommended storage conditions

- Solubility

- Slightly soluble in water; miscible with most organic solvents

- Transport

- UN Number: 1593, Class 6.1 (Toxic Substances)

- Toxicity

- Harmful if inhaled or swallowed; causes skin and eye irritation

- Odor Threshold

- 200 ppm

- Regulatory Status

- Conforms to relevant chemical safety and quality standards

- Shelf Life

- 24 Months from date of manufacture

- Refractive Index

- 1.4242 (at 20C)

- Autoignition Temperature

- 556C

- Flash Point

- None (non-flammable in air)

- Packing

- 250 kg Drum, ISO Tank, Bulk

- Evaporation Rate

- 27.5 (butyl acetate=1)

- Peroxides Content

- 0.0001%

- Density

- 1.325 g/cm at 20C

Methylene Dichloride MDC Trade Information

- Minimum Order Quantity

- 25 Kilograms

- Payment Terms

- Letter of Credit (L/C), Western Union, Paypal, Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 500 Kilograms Per Week

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Western Europe, Australia, Eastern Europe, Middle East, South America, Asia, Central America, North America, Africa

- Main Domestic Market

- All India

About Methylene Dichloride MDC

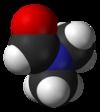

MDC

We at Antares Chem Pvt. Ltd. are offering quality range of Methylene Di Chloride MDC. The volatility and ability of the chemical to dissolve a wide range of organic compounds makes it a useful solvent for many chemical processes. Our range is formulated using high quality raw chemicals at our well established manufacturing unit as per the latest technology. Applications: Adhesives for Polymethyl Methacrylate Aerosol Propellant, Refrigerant Chemical Reaction Media Low-temperature heat-transfer medium Formulation of Polycarbonates, Phenolics, Rayon yarn Used as solvent for Cellulose Acetates, Photo-resist, Tablet film coatings Paint and Grease Removing Agent Fire-Fighting Agent Extract-ant for Edible fats, Cocoa, Butter and Essences.

Specification

| Physical State | Liquid |

| Packaging Type | Drum |

| Packaging Size | 250 Kgs |

| Usage | Cleaning |

| Grade Standard | Pharmaceutical |

| Purity (%) | 99.5 |

| Density (g/Cm Cube) | 1.3266 |

| Melting Point (deg. Celsius) | (96.7) |

| CAS Number | 75-09-2 |

Versatile Industrial Solvent

MDC offers exceptional solvency for a variety of applications, particularly in the production of adhesives, pharmaceuticals, and paint removers. Its miscibility with most organic solvents and rapid evaporation make it a preferred choice in extraction processes and metal cleaning industries.

Safety and Handling

Although methylene dichloride is non-flammable and stable under recommended storage conditions, it is toxic if inhaled or swallowed and can cause irritation to skin and eyes. Proper handling, storage in ventilated areas, and use of personal protective equipment are essential for safe usage.

Regulatory Compliance and Packaging

Our MDC conforms to relevant chemical safety and quality standards, identified by UN Number 1593 and HS Code 29031200. The product is supplied in secure packaging options suitable for large-scale industrial requirements, supporting safe transport and extended shelf life.

FAQs of Methylene Dichloride MDC:

Q: How should Methylene Dichloride (MDC) be safely stored and transported?

A: MDC should be kept in a cool, well-ventilated area away from heat and ignition sources. Transport is regulated under UN Number 1593, Class 6.1 (Toxic Substances), and it is typically shipped in 250 kg drums, ISO tanks, or in bulk according to international safety regulations.Q: What are the main industrial uses of MSD (Dichloromethane)?

A: MDC is primarily used as a solvent in paint removers, adhesives, pharmaceuticals, metal cleaning, and various extraction processes due to its rapid evaporation rate and high solvency power.Q: When is it necessary to use personal protective equipment with MDC?

A: Personnel should use appropriate protective equipmentsuch as gloves, goggles, and respiratory protectionwhenever handling MDC, as it is harmful if inhaled or swallowed and can irritate skin or eyes.Q: Where is MDC commonly supplied from and what is its purity?

A: MDC is produced and exported chiefly from India, with an assay typically not less than 99.9% purity. It conforms to international quality standards for industrial and pharmaceutical use.Q: What is the benefit of using MDC as a solvent in industrial applications?

A: The primary advantage is its effectiveness in dissolving a wide range of substances, its rapid evaporation, and its compatibility with most organic solvents, making it highly efficient for cleaning, extraction, and formulation processes.Q: How does MDCs physical property impact its handling in process applications?

A: With a low boiling point (39.6C) and high vapor pressure, MDC evaporates quickly, aiding in efficient drying and cleaning, but also requires careful ventilation to manage vapor exposure during use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pharma Chemicals Category

Methylene Di Chloride - MDC

Price 47 INR

Minimum Order Quantity : 25 Kilograms

Purity : 99.9%

Application : Other, Solvent for adhesives, pharmaceuticals, chemical processing, paint stripping

Usage : Paint remover, degreasing agent, solvent in chemical processes, pharmaceuticals, paint, coatings, adhesives, metal cleaning

Storage : Other, Store in a cool, dry, wellventilated area away from direct sunlight and incompatible substances

Acetonitrile

Price 160 INR

Minimum Order Quantity : 25

Purity : 99.9%

Application : Other, Pharmaceuticals, Organic Synthesis, Laboratory, Analytical Reagent

Usage : Pharmaceutical Intermediates, HPLC Solvent, Laboratory Use, Synthesis

Storage : Other, Keep tightly closed, Store in a cool and dry place

Methylene Dichloride (MDC)

Price 47 INR

Minimum Order Quantity : 25 Grams

Purity : 99.9%

Application : Other, Solvent in Paint, Pharmaceutical, Metal Cleaning

Usage : Pharmaceuticals, Paint Remover, Solvent

Storage : Other, Store in tightly closed containers, in a cool, dry, and wellventilated area

DMF

Price 60 INR

Minimum Order Quantity : 25 Kilograms

Purity : 99.9%

Application : Other, Pharmaceuticals, Agrochemicals, Polymer and Film Production

Usage : Industrial

Storage : Other, Store in a cool, dry, wellventilated place, keep container tightly closed

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free