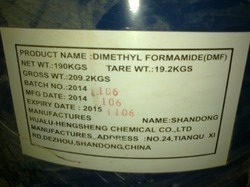

Dimethyl Formamide DMF

Dimethyl Formamide DMF Specification

- Assay

- Min 99.9%

- Particle Size

- N/A (Liquid)

- Ph Level

- 6.5 8 (20C, 50g/l H2O)

- Moisture (%)

- Max 0.05%

- Molecular Weight

- 73.09 g/mol

- Place of Origin

- India

- Acid Value

- Maximum 0.01 mg KOH/g

- HS Code

- 29241900

- Viscosity

- 0.802 cP at 25C

- Heavy Metal (%)

- <0.0005%

- Residue on Ignition

- Max 0.001%

- Molecular Formula

- C3H7NO

- Melting Point

- -61C

- EINECS No

- 200-679-5

- Storage

- Store in tightly sealed containers, cool and ventilated place

- Boiling point

- 153C

- Other Names

- N,N-Dimethylformamide; DMF

- CAS No

- 68-12-2

- Type

- Solvent

- Grade

- Industrial, Pharma

- Usage

- Industrial; Pharmaceutical; Agrochemical

- Purity

- 99.9%

- Appearance

- Clear liquid

- Application

- Solvent for acrylic fiber, plastics, pesticides, pharmaceuticals, adhesives

- Raw Material

- CO, CH3NH2

- Smell

- Slight, amine-like

- Color

- Colorless

- Form

- Liquid

- Water Solubility

- Miscible

- Shelf Life

- 24 months under proper storage

- Refractive Index (n20/D)

- 1.430 1.432

- Autoignition Temperature

- 445C

- Odor Threshold

- ~100 ppm

- Packaging

- Steel drums / ISO tanks / IBCs

- Toxicity

- Harmful if swallowed, inhaled, or absorbed through skin

- Flash Point

- 58C (Closed cup)

- Density

- 0.944 g/cm at 20C

- Conductivity

- 2.9 S/cm

- Vapor Pressure

- <0.05 mmHg at 25C

Dimethyl Formamide DMF Trade Information

- Minimum Order Quantity

- 25 Kilograms

- Payment Terms

- Letter of Credit (L/C), Western Union, Paypal, Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 500 Kilograms Per Week

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Eastern Europe, Central America, Middle East, South America, Western Europe, Australia, Asia, North America, Africa

- Main Domestic Market

- All India

About Dimethyl Formamide DMF

Dimethyl Formamide DMF

Being a quality centric company, we are presenting an outstanding quality of Dimethylformamide. Our client can purchase this propane with different packaging options only at suitable rates.

Features & Uses:

- Highly effective

- Quick and fast results

- Purity

- It is used as a reagent in the Bouveault aldehyde synthesis and in the Vilsmeier-Haack reaction, another useful method of forming aldehydes.

- It is also a common catalyst used in the synthesis of acyl halides, in particular the synthesis of acyl chlorides from carboxylic acids using oxalyl or thionyl chloride. The catalytic mechanism entails reversible formation of an imidoyl chloride.

Specification

| Formula | C3H7NO |

| Physical State | Liquid |

| Usage | Industrial |

| Grade Standard | Technical Grade |

Applications and Benefits

DMF is widely used as a solvent due to its excellent miscibility and stability. It finds major roles in the production of acrylic fibers, plastics, pesticides, pharmaceuticals, and adhesives. Its high purity and consistent chemical properties make it highly suitable for industrial processes where solvent quality is paramount.

Safe Handling and Storage

Given DMFs harmful effects upon swallowing, inhalation, or skin contact, users should employ appropriate safety equipment. The material should be stored in tightly sealed containers within cool, well-ventilated spaces to maximize shelf life and minimize risks associated with exposure or ignition.

FAQs of Dimethyl Formamide DMF:

Q: How should Dimethyl Formamide (DMF) be stored for maximum shelf life?

A: DMF should be kept in tightly sealed containers, placed in a cool, well-ventilated location. Proper storage under these recommended conditions ensures a shelf life of up to 24 months, helping preserve its purity and physical properties.Q: What are the typical industrial uses of Dimethyl Formamide?

A: DMF is commonly employed as a solvent in the manufacture of acrylic fibers, plastics, pesticides, pharmaceuticals, and adhesives. Its high purity and water miscibility make it invaluable in applications requiring reliable solvent performance.Q: When should DMF be handled with extra precautions?

A: Extra precautions should be taken when handling DMF to avoid ingestion, inhalation, or skin absorption, as it is harmful in these circumstances. Adequate protective gear, such as gloves and goggles, is recommended whenever working with the substance.Q: Where is Dimethyl Formamide most commonly sourced from?

A: Dimethyl Formamide is manufactured and exported by suppliers in India, frequently available in various grades for industrial and pharmaceutical use.Q: What process ensures DMF achieves a purity of 99.9%?

A: Achieving a DMF purity of 99.9% involves precise chemical synthesis using raw materials like carbon monoxide and methylamine, followed by extensive purification steps, including distillation and quality assays to ensure minimal impurities.Q: How does using DMF as a solvent benefit manufacturing operations?

A: DMFs high level of miscibility with water and stability under a range of conditions enhance its effectiveness as a solvent, contributing to improved product consistency and efficiency across various manufacturing processes.Q: What packaging options are available for DMF shipments?

A: DMF can be supplied in steel drums, ISO tanks, and intermediate bulk containers (IBCs), accommodating diverse shipment volumes and facility requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pharma Chemicals Category

Butyl Cellosolve

Price 24200 INR

Minimum Order Quantity : 1 Dram

Storage : Other, Cool, Dry Place

EINECS No : 2039050

Boiling point : 171C

Appearance : Clear Liquid

Powder Cyclohexane

Price 75 INR

Minimum Order Quantity : 25 Kilograms

Storage : Other, Store in a cool, dry, wellventilated place away from heat and ignition sources

EINECS No : 2038062

Boiling point : 80.7C

Appearance : Fine crystalline powder

Methylene Dichloride MDC

Price 47 INR

Minimum Order Quantity : 25 Kilograms

Storage : Other, Store in cool, ventilated area away from heat and ignition sources

EINECS No : 2008389

Boiling point : 39.6C

Appearance : Clear Liquid

Ethyl Chloroformate

Price 26400 INR

Minimum Order Quantity : 1 Dram

Storage : Other, Store in a cool, dry, wellventilated area, away from heat and ignition sources

EINECS No : 2087607

Boiling point : 9496C

Appearance : Clear liquid

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS