Maleic Anhydride

Maleic Anhydride Specification

- HS Code

- 29171400

- Shelf Life

- 2 years in original packaging

- Refractive Rate

- 1.508

- CAS No

- 108-31-6

- Appearance

- White crystalline solid

- Poisonous

- Yes, toxic by inhalation or contact

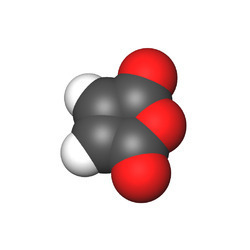

- Structural Formula

- 2 / 313cC4H2O3 (drawn as per standard structural formula with two double-bonded oxygens and an anhydride ring)

- Molecular Formula

- C4H2O3

- Application

- Production of unsaturated polyester resins, coatings, agricultural chemicals, plasticizers, copolymers

- Density

- 1.48 Gram per cubic centimeter(g/cm3)

- Molecular Weight

- 98.06 g/mol

- Grade

- Industrial Grade

- Ingredients

- Maleic Anhydride

- Solubility

- Soluble in acetone, benzene, slightly soluble in water

- Ph Level

- Acidic

- EINECS No

- 203-571-6

- Storage

- Store in a cool, dry, well-ventilated area, away from direct sunlight and moisture

- Shape

- Crystals/Powder

- Melting Point

- 52.8 C

- Smell

- Irritating, pungent odor

- Usage

- Intermediate for manufacturing resins and plasticizers, lubricating oil additives, paper sizing, water treatment chemicals

- Properties

- White free flowing powder, characteristic acrid odor, highly reactive, forms maleic acid on hydrolysis.

- Purity

- 99% Min

- Physical Form

- Powder

- Taste

- Not for taste, corrosive

- Product Type

- Organic Compound

- Boiling Point

- 202 C

- Safety Phrases

- S26, S36/37/39, S45

- Packing

- 25 kg, 500 kg bags, or as required

- Flash Point

- 102 C (closed cup)

- Hazards

- Causes burns, harmful if inhaled or ingested, may cause respiratory irritation

- Autoignition Temperature

- 477 C

- Stability

- Stable under normal conditions, reacts with water to form maleic acid

- Transport Information

- UN 2215, Class 8 (corrosive), Packing Group III

- Risk Phrases

- R23/24/25, R34

- UN Number

- 2215

- Vapor Pressure

- 0.08 mm Hg at 25 C

Maleic Anhydride Trade Information

- Minimum Order Quantity

- 25 Kilograms

- Payment Terms

- Letter of Credit (L/C), Western Union, Paypal, Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 500 Kilograms Per Week

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Western Europe, Australia, Middle East, Central America, Eastern Europe, South America, Asia, North America, Africa

- Main Domestic Market

- All India

About Maleic Anhydride

Maleic Anhydride

Surviving by transparent company policies, we are affianced in exporting, distributing, wholesaling, trading, retailing, importing and supplying an outstanding array of Maleic Anhydride. The offered Maleic anhydride is made with the advance technology & different chemical reactions according to the market norms. Our vendors experts of quality properly inspect this Maleic anhydride for its pure in nature and accurate composition. Along with that, consumers can purchase this Maleic anhydride in a bulk quantity at reasonable rates.

Features:

- Effective

- No side highly effective

- Water soluble

Specification

| Usage | Commercial |

| Usage | Industrial |

| Physical State | Granules |

| Grade Standard | Reagent Grade,Technical Grade |

Applications in Industry

Maleic Anhydride serves as a crucial raw material in the synthesis of unsaturated polyester resins, which are widely used in fiberglass-reinforced plastics, coatings, and adhesives. It also acts as an intermediate for plasticizers, agricultural chemicals, lubricating oil additives, and water treatment chemicals in industrial operations, ensuring high performance across various manufacturing sectors.

Safe Transport and Storage

Proper handling of Maleic Anhydride is essential due to its corrosive and toxic nature. The product is classified as UN 2215 (Class 8, Packing Group III) for transport and is typically supplied in 25 kg or 500 kg bags. To preserve quality and safety, it should be stored away from moisture and direct sunlight in a well-ventilated, cool, and dry area. Original packaging maintains its integrity for up to two years.

Key Physical and Chemical Properties

This compound is a white, free-flowing powder with a strong, acrid odor. Maleic Anhydride exhibits an acidic pH, a density of 1.48 g/cm, and a melting point of 52.8C. Its limited solubility in water, combined with high reactivity, makes it important for controlled processes. It hydrolyzes rapidly when exposed to moisture, forming maleic acid.

FAQs of Maleic Anhydride:

Q: How should Maleic Anhydride be safely handled and stored?

A: Handle Maleic Anhydride in a well-ventilated area, using protective gloves, clothing, and eye protection as it is corrosive and toxic. Store it in its original packaging in a cool, dry, well-ventilated space, away from moisture and sunlight, to preserve its stability and safety for up to two years.Q: What are the primary industrial uses of Maleic Anhydride?

A: Maleic Anhydride is primarily used in the production of unsaturated polyester resins, coatings, plasticizers, agricultural chemicals, copolymers, and lubricating oil additives. It acts as a vital intermediate in the chemical industry, supporting the manufacturing of diverse materials and chemicals.Q: When does Maleic Anhydride decompose or react, and what are the associated hazards?

A: Maleic Anhydride remains stable under normal conditions, but reacts rapidly with water to form maleic acid. Decomposition occurs when exposed to excessive heat, potentially releasing toxic fumes. Inhalation, ingestion, or direct contact can cause severe burns and respiratory irritation.Q: Where is Maleic Anhydride typically applied or processed?

A: This compound is processed in chemical manufacturing plants, resin production facilities, and industries involved in producing coatings, paper, and water treatment chemicals. Its applications span industrial sectors where it is handled by trained personnel with appropriate safety equipment.Q: What are the transport regulations for Maleic Anhydride?

A: Maleic Anhydride must be transported according to international regulations as a corrosive substance (UN 2215, Class 8, Packing Group III). It is usually shipped in 25 kg or 500 kg bags, with labeling and packaging requirements strictly followed to ensure safety during transit.Q: How is Maleic Anhydride beneficial in manufacturing processes?

A: Due to its high reactivity and purity, Maleic Anhydride enables efficient production of high-performance resins, additives, and specialty chemicals. Its use contributes to enhanced product quality and process versatility across several industries, supporting modern material advancements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Chemicals Powders Category

Hydrazine Hydrate

Price 47300 INR

Minimum Order Quantity : 1 Dram

Shelf Life : 12 months in unopened original packaging

Storage : Other, Store in a cool, dry, ventilated area away from sunlight and incompatible substances

Purity : 80% Min

Application : Other , Used as oxygen scavenger in boiler water treatment, in manufacturing pharmaceuticals, agricultural chemicals, polymers, blowing agents, and as a rocket fuel propellant

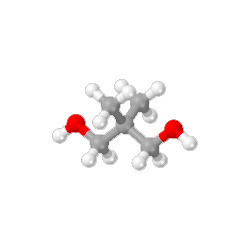

Neopentyl Glycol

Price 80 INR

Minimum Order Quantity : 25 Kilograms

Shelf Life : 2 years

Storage : Other, Store in cool, dry, wellventilated area

Purity : Min 99.0%

Application : Other , Used as intermediate in production of polyesters, paints, lubricants, plasticizers

Copper Cyanide

Price 575 INR

Minimum Order Quantity : 25 Kilograms

Shelf Life : 2 years if stored properly

Storage : Other, Store in a tightly sealed container in a cool, dry place, away from acids and water

Purity : 98% Min

Application : Other , Electroplating, metallurgy, insecticide, chemical manufacturing

PTSA Powder

Price 75 INR

Minimum Order Quantity : 25 Kilograms

Shelf Life : 24 months

Storage : Other, Keep container tightly closed in a cool, dry place; protect from light

Purity : >98%

Application : Other , Water tracer, leak detection, fluorescent indicator, research, industrial dye

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free