Tetraethylene Pentamine

Price 320 INR/ Kilograms

Tetraethylene Pentamine Specification

- EINECS No

- 203-986-2

- Molecular Weight

- 189.32 g/mol

- Acid Value

- <1 mg KOH/g

- Particle Size

- Not applicable (liquid)

- Residue on Ignition

- 0.1%

- Assay

- 98%

- Heavy Metal (%)

- 0.001%

- Boiling point

- 335 C

- HS Code

- 29212990

- Ph Level

- Alkaline

- Melting Point

- -30 C

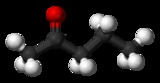

- Molecular Formula

- C8H23N5

- Place of Origin

- India

- Storage

- Store in a cool, ventilated place; keep container tightly closed

- Viscosity

- 18 mPas (25C)

- Loss on Drying

- 0.5%

- Moisture (%)

- 0.5%

- Other Names

- TEPA, Tetraethylene-1,5-diamine

- CAS No

- 112-57-2

- Type

- Industrial Chemical

- Grade

- Technical Grade

- Usage

- Epoxy curing agent, Oil additive, Corrosion inhibitor, Chelating agent

- Purity

- >98%

- Appearance

- Clear liquid

- Application

- Used in the manufacture of surfactants, lubricants, fuel additives, and additives for oil field chemicals

- Raw Material

- Ethylene dichloride

- Smell

- Ammoniacal

- Color

- Colorless to pale yellow

- Form

- Liquid

- Flash Point

- 154°C (Closed cup)

- Density

- 0.983 g/cm³ @ 20°C

- Solubility

- Completely miscible with water

- Shelf Life

- 12 months from date of manufacturing if unopened

- Stability

- Stable under recommended storage conditions

- Packaging

- Drum, IBC, bulk

- Refractive Index

- 1.486 @ 20°C

Tetraethylene Pentamine Trade Information

- Minimum Order Quantity

- 25 Kilograms

- Payment Terms

- Cash Advance (CA), Letter of Credit (L/C), Western Union, Paypal, Cash in Advance (CID)

- Supply Ability

- 500 Kilograms Per Week

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Western Europe, Australia, North America, South America, Eastern Europe, Middle East, Asia, Central America, Africa

- Main Domestic Market

- All India

About Tetraethylene Pentamine

Triethylene Pentamine

With the inclusion of advanced technology, we are engaged in offering a comprehensive range of Triethylene Pentamine. The range offered by us is strictly processed utilizing premium quality chemical compounds and advanced techniques in strictly adhering to set industrial standards. Apart from this, we offer this product in varied packaging options in order to satisfy variegated demands of our clients spanning all over the world.

Features:

- Long shelf life

- Purity

- No side effects

Specification

| Purity | 99% |

| Physical State | Liquid |

| Usage | Industrial |

| Grade Standard | Technical Grade |

Exceptional Stability and Quality

With a purity of over 98% and an alkaline profile, TEPA ensures reliability across multiple industrial operations. Its stability under recommended storage ensures consistent performance throughout its 12-month shelf life. Carefully controlled for moisture, heavy metals, and other residues, this product guarantees the high standards demanded by global manufacturers.

Versatile Industrial Utility

TEPAs versatility makes it invaluable as an epoxy curing agent, corrosion inhibitor, oil additive, and chelating agent. It is pivotal in producing surfactants, lubricants, and various fuel additives. Its clear liquid form and complete miscibility with water facilitate ease of handling and incorporation into diverse chemical processes.

FAQs of Tetraethylene Pentamine:

Q: How should Tetraethylene Pentamine (TEPA) be stored for optimal stability?

A: Store TEPA in a tightly sealed container in a cool, well-ventilated area away from direct sunlight. Proper storage ensures the product maintains its stability and a shelf life of up to 12 months from the date of manufacturing if unopened.Q: What are the primary industrial uses of TEPA?

A: TEPA is widely used as an epoxy curing agent, corrosion inhibitor, oil additive, and chelating agent. It also serves as a key component in the production of surfactants, lubricants, and oil field chemical additives.Q: When is TEPA typically added during the manufacturing process?

A: TEPA is introduced during the formulation or compounding stages, especially when used as a curing agent for epoxies or as an additive in oil and lubricants, to ensure proper chemical integration and desired end-product performance.Q: Where is your TEPA manufactured and exported from?

A: Our Tetraethylene Pentamine is produced and exported from India, complying with international quality and safety standards for shipment globally.Q: What benefits does TEPA offer in industrial applications?

A: TEPAs high purity, strong chelating ability, and complete miscibility with water enhance efficiency and effectiveness across processes. Its stability and long shelf life provide added value, making it cost-effective for large-scale industrial use.Q: How is TEPA typically packaged for delivery?

A: The product is available in various packaging formats including drums, Intermediate Bulk Containers (IBC), and bulk tanks, accommodating different volume requirements and transportation needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pharmaceutical Chemicals Category

Triethanolamine

Price 95 INR

Minimum Order Quantity : 25 Kilograms

Application : Other, Textile, Detergents, Cosmetics, Pharmaceuticals

Storage : Other, Cool and Dry Place

Purity : 99% min

Molecular Formula : C6H15NO3

Methyl n-Propyl Ketone

Price 475 INR

Minimum Order Quantity : 25 Kilograms

Application : Other, Used as a solvent in coatings, adhesives, and inks

Storage : Other, Store in a cool, dry, wellventilated area, tightly closed

Purity : 99%

Molecular Formula : C5H10O

Hydrobromic Acid

Price 26250 INR

Minimum Order Quantity : 1 ,

Application : Other, Pharmaceutical API intermediate, Bromination agent, Laboratory reagent, Chemical synthesis

Storage : Other, Store in tightly closed container, in a cool, dry, wellventilated area away from incompatible substances

Purity : 48%

Molecular Formula : HBr

Triethyl Orthoformate

Price 34000 INR

Minimum Order Quantity : 1 Dram

Application : Other, Used as reagent for formylation, in active pharmaceutical ingredient synthesis, and fermentation processes

Storage : Other, Store in a cool, dry, wellventilated area, away from heat and sources of ignition

Purity : 99.0%

Molecular Formula : C7H16O3

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free