Powder Cyclohexane

Powder Cyclohexane Specification

- Viscosity

- Not applicable (solid at room temp)

- Moisture (%)

- <0.2%

- Melting Point

- 6.5C

- Molecular Weight

- 84.16 g/mol

- Particle Size

- Typically <50 micron

- HS Code

- 29021100

- Molecular Formula

- C6H12

- Heavy Metal (%)

- 0.001%

- Ph Level

- Neutral

- Assay

- >= 99%

- Storage

- Store in a cool, dry, well-ventilated place away from heat and ignition sources

- Residue on Ignition

- 0.05%

- Boiling point

- 80.7C

- EINECS No

- 203-806-2

- Place of Origin

- India

- Loss on Drying

- 0.3%

- Other Names

- Hexahydrobenzene, Hexamethylene, Ketohexamethylene

- CAS No

- 110-82-7

- Type

- Powder

- Grade

- Industrial grade

- Usage

- Industrial chemical, solvent, intermediate

- Purity

- 99%

- Appearance

- Fine crystalline powder

- Application

- Used as a solvent, chemical intermediate, and for synthesis of nylon

- Raw Material

- Cyclohexanone, Benzene

- Smell

- Faint, characteristic odor

- Color

- White to off-white

- Form

- Powder

- Stability

- Stable under recommended storage conditions

- Minimum Order Quantity

- 25 Kg

- Density

- 0.778 g/cm³ at 20°C

- Refractive Index

- n20/D 1.4265

- UN Number

- UN1145

- Packing Group

- II

- Flash Point

- -20°C (closed cup)

- Packaging

- 25 Kg fiber drum or as per client requirement

- Hazard Class

- Hazardous, Flammable solid

- Shelf Life

- 2 years when properly stored

- Solubility

- Insoluble in water; soluble in alcohol, ether, acetone

Powder Cyclohexane Trade Information

- Minimum Order Quantity

- 25 Kilograms

- Payment Terms

- Western Union, Paypal, Letter of Credit (L/C), Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 500 Kilograms Per Week

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Western Europe, Australia, South America, Eastern Europe, Middle East, Central America, Asia, North America, Africa

- Main Domestic Market

- All India

About Powder Cyclohexane

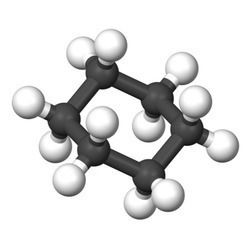

Cyclohexane

Cyclohexane is a cycloalkane with the molecular formula C6H12.

Use : Cyclohexane is used in a number of industrial applications. The primary use of cyclohexane, accounting for approximately 58 percent of all use, is in the production of adipic acid, a nylon intermediate. Cyclohexane is also used in the production of caprolactam, another nylon intermediate. Small amounts are used as a solvent for lacquers and resins; as a paint and varnish remover; as an intermediate in the manufacture of benzene, cyclohexanone, and itrocyclohexane; as fuel for camp stoves; as an ingredient in fungicidal formulations; and in the industrial recrystallization of steroids

Specification

| Density | 779 kg/m3 |

| Physical State | Powder |

| Usage | Industrial,Commerical |

| Molar mass | 84.16 g/mol |

| Density | 779 kg/m3 |

| Physical State | Powder |

| Usage | Industrial,Commerical |

| Molar mass | 84.16 g/mol |

Versatile Industrial Applications

Powder Cyclohexane is widely utilized in various industrial settings, notably as a solvent and as a precursor in the manufacture of nylon and other chemicals. Its high purity and reliable performance enable efficient chemical syntheses, making it essential for manufacturers, suppliers, and exporters across the chemical industry.

Safe Handling and Storage

Given its flammability (flash point: -20C) and hazardous classification, Powder Cyclohexane requires storage in tightly sealed containers, away from heat sources and ignition points. Appropriate storage ensures product stability and a shelf life of two years. Always adhere to recommended safety guidelines for handling and storage.

Quality and Specifications

This product is supplied as a fine crystalline powder, with particles typically less than 50 microns and extremely low impurity levels. It is manufactured under stringent quality controls, guaranteeing an assay of 99%, minimal moisture (<0.2%), and trace heavy metals (0.001%). Custom packaging is available to meet client requirements.

FAQs of Powder Cyclohexane:

Q: How should Powder Cyclohexane be stored and handled safely?

A: Powder Cyclohexane must be stored in a cool, dry, well-ventilated area away from sources of heat and ignition. Use appropriate personal protective equipment when handling, as it is classified as a flammable and hazardous solid (Hazard Class: Flammable solid, UN1145). Ensure containers are tightly closed and follow standard industrial safety protocols.Q: What are the primary industrial uses of Powder Cyclohexane?

A: Powder Cyclohexane is primarily used as a solvent, chemical intermediate, and a key raw material in the synthesis of nylon. Its high purity and solubility in organic solvents such as alcohol, ether, and acetone make it valuable for various chemical manufacturing processes.Q: When is Powder Cyclohexane considered stable, and what is its shelf life?

A: Under recommended storage conditionscool, dry, and away from ignition sourcesPowder Cyclohexane remains stable and maintains its properties for up to two years from the date of manufacture.Q: Where does your Powder Cyclohexane originate, and in what packaging is it supplied?

A: Our Powder Cyclohexane is manufactured and exported from India. It is typically packaged in 25 kg fiber drums, although custom packaging solutions can be provided as per client requirements.Q: What is the recommended process for using Powder Cyclohexane as an industrial solvent or intermediate?

A: During use, ensure the work area is well-ventilated and avoid exposure to sources of ignition. Due to its fine crystalline nature and high flammability, carefully measure and blend Powder Cyclohexane into processes requiring a non-aqueous solvent or chemical intermediate, strictly adhering to safety measures.Q: How does Powder Cyclohexane benefit chemical synthesis and industrial applications?

A: Powder Cyclohexane offers high efficiency in chemical reactions due to its high purity (99%) and excellent solubility in common organic solvents. Its neutral pH and low impurity profile support consistent results, particularly in polymer and nylon synthesis, enhancing both yield and product quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pharma Chemicals Category

Liquid DMF Solvent

Price 15400 INR / Dram

Minimum Order Quantity : 1 Dram

Storage : Other, Store in tightly closed containers, in a cool and dry place

Purity : 99.9%

Grade : Other, Industrial Grade

Form : Liquid

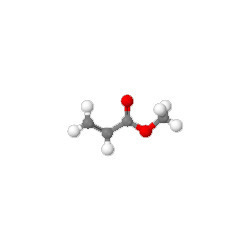

Liquid Methyl Acrylate

Price 120 INR

Minimum Order Quantity : 25 Kilograms

Storage : Room Temperature

Purity : 99%

Grade : Tech Grade

Form : Other

PEG 400

Price 19550 INR

Minimum Order Quantity : 1 Dram

Storage : Other, Keep container in a cool, wellventilated area

Purity : 99%

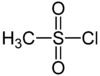

Methane Sulphonyl Chloride

Price 175 INR

Minimum Order Quantity : 25 Kilograms

Storage : Room Temperature

Purity : 99.5 %

Grade : Tech Grade

Form : Liquid

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free